Integrated Solutions to Intricate Components

Using a wide range of metal working processes – Die/Mould Making, Pressure Die Casting, Precision Machining, Surface Treatment

Manufacturing with Assurance Reliability and Service

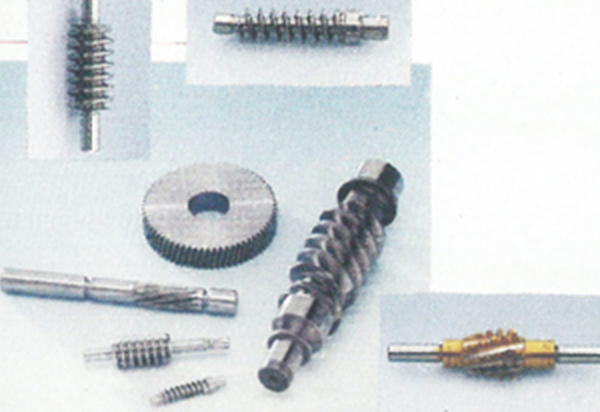

Backward and forward integrated activities like continuous casting of cooper alloys, solid carbide cutting tools, fixtures and gauge manufacturing, to ensure core manufacturing services, reduce development lead time and control on processes